The mission was to create a pop-up (lift top) coffee table that had dual tops so that when my significant other and I are sitting on the couch, one of us could have their side up and the other one could leave theirs down. I’m going to upload the drawings and step by step instructions shortly!

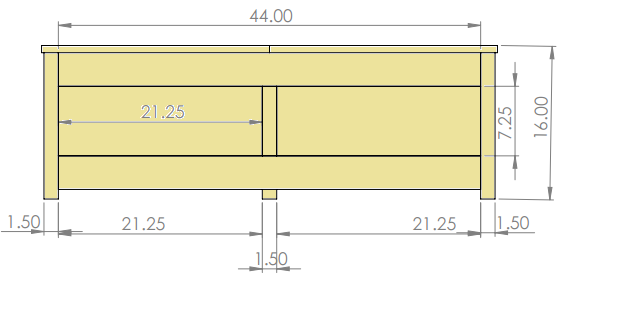

DIMENSIONS

Approximately 47.5″ x 26″ x 16″

PREPARATION

- Clamps! SO MANY CLAMPS!

Wood glue - Number of boards Size (nominal)

Oak (nice wood for show pieces):

- 1 1x4x6

- 3 1x4x8

- 2 1x8x8

- 3 2x2x3

- 2 1x12x6

Pine/poplar (whatever is cheap):

- 2 1x2x8

- 1 1x4x6

- 2 1x6x8

- 1 2x2x8

Also needed:

- Half sheet of 1/2″ plywood

- Whole Sheet of 1/8″ plywood (drawer bottoms)

- 10″ drawer slides (found on Amazon)

Drawer hardware

- 3/4 inch screws

- 1-1/4″ Pocket Hole Screws

- paint brush

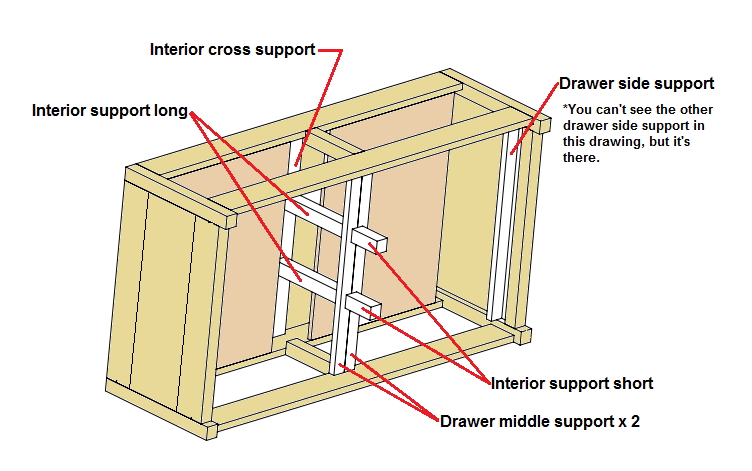

Table Frame:

- 4 x Side trim 0.75×3.5×22.5

- 2 x Sides 0.75×7.25×22.5

- 4 x Legs 1.5×1.5×15.25

- 2 x Front/Back Vertical 1.5×1.5×7.25

- 4 x Front/Back Horiz. 0.75×3.5×45.5

- Drawer Mid. Supports 0.75×1.5×24

- Drawer Side Supports 0.75×1.5×22.5

- Interior Support Long 1.5×1.5×9.8125

- Interior support Short 1.5×1.5×3.75

- Interior Cross Support 0.75×3.5×24

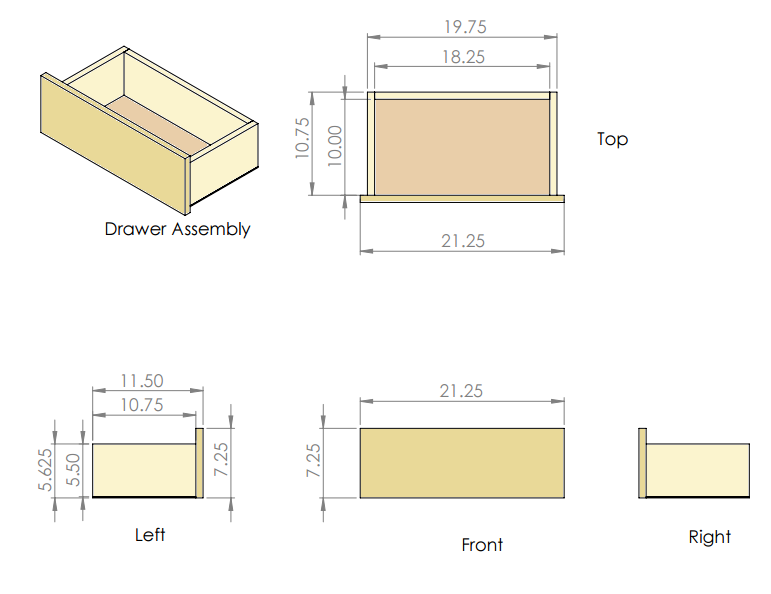

Drawers:

- 4 x Drawer Face 0.75×7.25×22

- (you might cut about 1/8″ off all sides of the drawer face to fit flush in the frame instead of outside like mine)

- 8 x Drawer Side 0.75×5.5×10.75

- 4 x Drawer Back 0.75×5.5×18.25

- 4 x Drawer Bottom 0.125×10.75×19.75

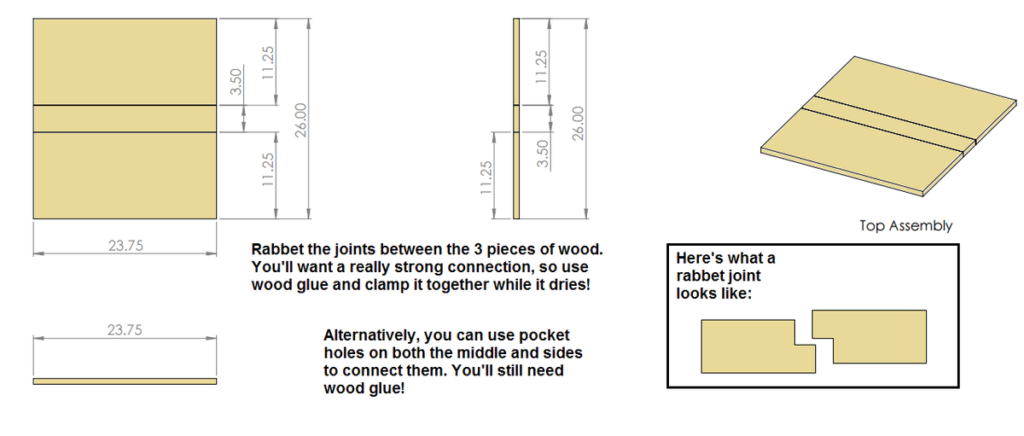

Tops:

- 4 x Front and Back 0.75×11.25×24.5

- 2 x Middle 0.75×3.5×24.5

INSTRUCTIONS

STEP 1

Make all the cuts. I put the actual dimensions of the boards. For the complete novice, don’t forget that when I say 0.75, I mean 3/4″, and if a cut has a dimension of 0.75×3.5×22.5, that means you’ll be cutting a 22.5″ from a 1″x4″ board. If you bought your lumber from L0wes or H0meDep0t, a 1″x4″x8′ board will actually be 3/4″ x 3.5″ x 8′ because of how much they plane off to make the sides smooth.

My advice to you is to keep the tops, drawers, and frame parts separate. It’s going to be a big pile of wood, and you don’t want to put a pocket hole where it doesn’t belong!

STEP 2

At this point, I decided to put together the tops. If you bought some really straight oak boards, you’ll probably be looking at a pretty good fit together. If you bought some not so straight boards, you may end up having to take a bit off with a jointer (or a router, like I did). Otherwise, you’ll get gaps, and that’ll look weird.

Get your 1″ x 12″ tops, and the 1″ x 4″ middles, and pick the best matches. Look at the grain and color of the wood and just take your best guess. If you’re going to use pocket holes to join them, you’ll want them on both sides. You’ll also need to use wood glue and some pretty large clamps to hold them together for you. It’s a process. If you don’t want to use pocket holes, you can make a much stronger joint by rabbeting the interior edges with a router. Watch a lot of youtube videos before you try it for your first time, and definitely practice on some scraps!! This is where I ended up having to take too much off, and it left my tops a little short.

STEP 3

Drawers!

These should be pretty simple. You’ll use pocket holes to put together the sides and backs. I used a brad nailer to attach the 1/8″ plywood bottoms. I didn’t attach the faces at this point because I wanted to stain/finish them first. You can attach them now and stain/poly after the fact if you want. I saved the drawer hardware for the very, very end of the project. The drawer slides should wait until you’ve got the frame assembled to help you figure out where to mount them.

STEP 4

Pocket holes! Pocket holes EVERYWHERE!

Get out your kreg jig, and start making pocket holes. You’ll need them on the 1x4x45.5’s in three spots (sides and the middle where the verticals mount), all of the side pieces, and the really short oak middle pieces. You’ll also need them on the interior supports. Since the vast majority of your connections are 3/4″ to 3/4″ wood, you’ll need mostly only 1-1/4″ pocket hole screws, and you won’t need to reset your kreg jig for much of anything.

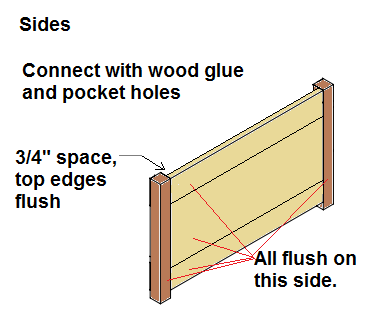

STEP 5

Assembly

Time to put together the sides. You should have already put pocket holes in the backs of the 1×4’s and the 1×8’s, so get your clamps out. I suggest getting one leg, start with one of the 1×4’s, make it flush to the top of the leg, glue the edge, and then screw it on. Then get the 1×8, glue the edge (top and leg side), then clamp it flush to the leg and the 1×4, then screw it in. Next, grab the second 1×4, glue the top and side edge, clamp to the already installed parts, and screw it in. Wipe the excess glue away fast!! It’ll harden and then turn into a gross mess otherwise. Finally, glue the opposite edges of the 1×4’s and 1×8, and clamp the other leg in place. Carefullly line it up, clamp it together, and make it flush. Screw it together, and you’ve got a side (pictured above).

STEP 6

Now that you’ve got the sides, it’s time to mount those long pieces in the front. Mount the top 1x4x45.5 piece flush to the top of the legs. Use wood glue and at least two pocket holes to attach them. Measure carefully down or use the front/back verticals (1.5×1.5×7.25) to figure out exactly where to mount the bottom 1x4x45.5. You’ll start seeing the shape of the coffee table come together now!

STEP 7

Interior support structure…

You’ll need to mount those front/back verticals with pocket holes. Measure VERY CAREFULLY to find the exact middle of your 1x4x45’s horizontals, and that’ll tell you where to mount them. I actually drilled the pocket holes in the 1x4x45.5’s exactly in the middle back in step 2. If you’ve gotten all of the pocket holes drilled for the supports, this will go pretty quickly. You’ll notice that I’ve left space for the lift hardware. This is important, or the tops won’t sit flush. The picture doesn’t show all of the supports. You’ll need left and right side supports to hold the lift mechanism. I think it should be fairly obvious about where they mount, and they’re in the cut list. Just make sure they’re about 3/16″ low to account for the thickness of the metal on the lift mechanism.

FINISHING INSTRUCTIONS

Fill all holes with wood filler and let dry. Apply additional coats of wood filler as needed. When wood filler is completely dry, sand the project in the direction of the wood grain with 120 grit sandpaper. Vacuum sanded project to remove sanding residue. Remove all sanding residue on work surfaces as well. Wipe project clean with damp cloth. Sand it all again with 220 grit sand paper!

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.

CREDIT DAVE M